SAP EHS DISCUSSIONS !!!!

This site is dedicated for Project implementation discussions, future market, product development and all your views on SAP EH&S, REACh and Product Compliance, SAP Carbon Impact, Environmental Compliance.

Saturday, July 21, 2018

Saturday, July 15, 2017

Fundamentals of Implementing a Product Safety Module - Topic 2 Data Migration:

Hello,

As it is evident in all implementation projects, consultants needs to set up the master data during the initial system set up and move the legacy data. There are different methods one can follow to load the data into the system. The pre-requisite is cleansing the data and modifying the content and formatting the information into to a specified layout. There are different tools available to load the information into the SAP EHS systems. The different tools which can be used include i) SAP EHS OCC and ii) Data Editor and iii. Custom Excel templates.

The tools namely Data Editor has two functionalities called PIT and SIT. Phrase Import Tool and Substance Import Tool. While SAP EHS OCC has similar functionality like Data Editor It has different options of loading the content with different validity / Usage area information directly from the import tool and also deleting the content and loading the information.

In order to load the content into the system it is always useful to load in sequences and parts like start with creation of Header Information, followed by Identifiers, references, Material assignments and property data and then compositions. Usually the Listed substances are created first, followed by Raw Substances / Vendor / Raw Substances. Then substances are loaded at product level.

For each of the data load there are two possibilities exist one is online load and other one is offline load. During online load system directly writes the data to the specification data, whereas during offline mode system generates a Dat File to load the information.

The sequences of steps you follows to load the data include i) Maintaining the data ii) saving as tab delimited Txt file iii) converting the dat file and importing the dat file into the system for directly loading the content to database following the step ii.

Once data is migrated system is checked for accuracy of the information and used for different substance maintenance.

Thanks

As it is evident in all implementation projects, consultants needs to set up the master data during the initial system set up and move the legacy data. There are different methods one can follow to load the data into the system. The pre-requisite is cleansing the data and modifying the content and formatting the information into to a specified layout. There are different tools available to load the information into the SAP EHS systems. The different tools which can be used include i) SAP EHS OCC and ii) Data Editor and iii. Custom Excel templates.

The tools namely Data Editor has two functionalities called PIT and SIT. Phrase Import Tool and Substance Import Tool. While SAP EHS OCC has similar functionality like Data Editor It has different options of loading the content with different validity / Usage area information directly from the import tool and also deleting the content and loading the information.

In order to load the content into the system it is always useful to load in sequences and parts like start with creation of Header Information, followed by Identifiers, references, Material assignments and property data and then compositions. Usually the Listed substances are created first, followed by Raw Substances / Vendor / Raw Substances. Then substances are loaded at product level.

For each of the data load there are two possibilities exist one is online load and other one is offline load. During online load system directly writes the data to the specification data, whereas during offline mode system generates a Dat File to load the information.

The sequences of steps you follows to load the data include i) Maintaining the data ii) saving as tab delimited Txt file iii) converting the dat file and importing the dat file into the system for directly loading the content to database following the step ii.

Once data is migrated system is checked for accuracy of the information and used for different substance maintenance.

Thanks

Sunday, July 9, 2017

Fundamentals of Implementing a Product Safety Module - Topic 1 significance of Data model:

Dear Friends,

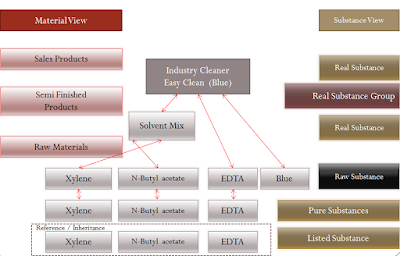

One

of the significant steps while implementing the Product Safety or any substance

database related module in SAP EHS is understanding the data model. Data model

defines how a company product is going to be represented in the SAP System. The

different substance types and their inter-relationships defines the overall

strategy. There are different data models available based on the company

requirements like a standard data model consist of Real Sub linked to Pure

Substances and Pure Substances are referenced / inheritance to pure substances.

This is the data model which is used for even meeting the substance volume

tracking and other functionalities. Example below shows the model

Figure showing a demo product structure

If you also have a DG into the overall company strategy the structure will differ with inclusion of Transport classification and Hazard Inducers information. The detail information about the different composition types and the way different components are mapped and their differentiation in to Polymers, monomer differentiation for Volume Tracking is another topic of importance to be checked while implementing the module. The strategy and direction depends on overall company direction and it should be properly analyzed before recommending a data model to an organization.

Thanks and Regards

Monday, March 18, 2013

SAP EHS and SAP EHSM – Where to start learning

Dear Friends,

Recently SAP started its new dimensional product SAP EHSM (SAP Environment Health and Safety Management System) as a business process driven product. SAP EHSM already seen major revisions like version 1 through version 3 with a version lined up for later this year; If one intends to learn SAP EHS and be a consultant which of the modules needs to be learned is it SAP EHS or SAP EHSM. SAP EHSM consists of Incident management, Risk Assessment, Worker Safety management and Product Compliance. SAP EHS consists of all the legacy EHS functionalities like Product Safety, Dangerous Goods Management, and Waste Management, Hazardous Substance Management, and Occupational health, besides Sustainability Performance Management, Management of Change, Environmental compliance and On Demand Solution SAP Carbon Impact. The major module which is revamped in SAP EHSM is Legacy SAP EHS Industrial Hygiene and Safety – consisting of Incident management and Risk Management, with the concept of business objects (BOPF) processing framework for flexibility and speed of execution.

If the nature of the job is on implementation of EHSM Incident Management, Risk Assessment or Management or Change or Product Compliance for meeting REACH requirements its ideal to learn EHSM directly without much difficulty. These modules work independently of legacy EHS, except for Product Compliance which requires Substance database business object framework; which are desinged to synchronize with EHSM. If the nature of work is legacy EHS – Global Label Management, Substance volume tracking, Product Safety, Dangerous Goods Management, Waste Management; are implemented as SAP ECC - EHS component.

SAP EHS – Basic Data and Tools, Product Safety, Dangerous Goods Management, Hazardous Substance Management, Substance Volume Tracking, Waste management and Occupational Health. Environmental compliance, SAP Carbon Impact, SAP EHSM Management of Change, SAP EHSM Incident Management, SAP EHSM Operational Risk Management and SAP EHSM Sustainability Performance Management and SAP EHSM Worker safety management are some of the modules which are available.

Thanks

Recently SAP started its new dimensional product SAP EHSM (SAP Environment Health and Safety Management System) as a business process driven product. SAP EHSM already seen major revisions like version 1 through version 3 with a version lined up for later this year; If one intends to learn SAP EHS and be a consultant which of the modules needs to be learned is it SAP EHS or SAP EHSM. SAP EHSM consists of Incident management, Risk Assessment, Worker Safety management and Product Compliance. SAP EHS consists of all the legacy EHS functionalities like Product Safety, Dangerous Goods Management, and Waste Management, Hazardous Substance Management, and Occupational health, besides Sustainability Performance Management, Management of Change, Environmental compliance and On Demand Solution SAP Carbon Impact. The major module which is revamped in SAP EHSM is Legacy SAP EHS Industrial Hygiene and Safety – consisting of Incident management and Risk Management, with the concept of business objects (BOPF) processing framework for flexibility and speed of execution.

If the nature of the job is on implementation of EHSM Incident Management, Risk Assessment or Management or Change or Product Compliance for meeting REACH requirements its ideal to learn EHSM directly without much difficulty. These modules work independently of legacy EHS, except for Product Compliance which requires Substance database business object framework; which are desinged to synchronize with EHSM. If the nature of work is legacy EHS – Global Label Management, Substance volume tracking, Product Safety, Dangerous Goods Management, Waste Management; are implemented as SAP ECC - EHS component.

SAP EHS – Basic Data and Tools, Product Safety, Dangerous Goods Management, Hazardous Substance Management, Substance Volume Tracking, Waste management and Occupational Health. Environmental compliance, SAP Carbon Impact, SAP EHSM Management of Change, SAP EHSM Incident Management, SAP EHSM Operational Risk Management and SAP EHSM Sustainability Performance Management and SAP EHSM Worker safety management are some of the modules which are available.

Thanks

Tuesday, October 11, 2011

Implementing SAP EHS in current Economic Scenario... Seeing Opportunity in Difficult Period !!!

Dear Friends,

As is evident from the market, majority of companies seeing to expand their ERP portfolio with Sustainability footprint, some focusing on entirely new implementations, some on Upgrade and some on the consolidation of their existing systems and recreating their solution landscape. So transitioning existing SAP systems with EHS portfolio has always been revolutionary, which takes entire Compliance process to next level, to a level where regulatory information is delivered more quickly, more informed decisions are made and ultimately an increased compliance and less violations is achieved. The trick is doing right with less resources and money. These transformations are almost always painful nonetheless owing to the fact that majority of the regulations or legal requirements are on continuous change. Further many Small and Mid sized organizations find it difficult to fully understood the legalities and are in the process of developing their own work processes.

There’s no value and no reason to reinvent the wheel i.e., Business Processes. Frankly, most everything a Company needs or want in regard to a Sustainability implementation has already been done, and done well, by Sector Specific SAP Best Practices. A Company job can be much simpler and certainly less risky because of them. This is often the case with Mid Sized Enterprises, when it comes to Large Companies the implementation spans across multiple years and multiple milestones. Expanding the existing ERP portfolio with EHS Suite is less often the innovative game, for many has become the required investment necessarily to merely re-level the playing fields. Often Business follows the Software while it is implemented so it’s often useful to implement the best practices and level the ground to meet the competition and then innovate as the days pass to achieve operational efficiency - this will reduce the risk, implement with less resources and moreover reduce the implementation cost.

Thanks

Jayakumar

Thursday, February 24, 2011

Choosing the right software for your EHS requirements

Dear Friends,

Now that majority of companies are seeing for expanding their EHS portfolio by implementing additional software components – it needs some research and understanding which software fits to the company. Even companies are not without any software processes– they have been operating with some internal tools and other application components to meet their day to day regulatory requirement. Now that they want to move out of the legacy tools and migrate to enterprise levels – they have some solutions in mind –either develop own tool, use software as a service or use the established tool from the ERP vendors on premise. The development of custom tools may seem attractive initially but the quality depends on the ability of the resource guiding its development and has a long term liability of support and maintenance – should only be driven by a strategic requirements.

When it comes to external software components there are many of products available in the market today each one promising its own ROI. So before a product is purchased some of the questions which needs to be assessed include – 1) what I am seeing for the product to do? Like GHS reporting, GHS management in Supply Chain, Product portfolio management using the Environmental information. So on depending on the module of interest? Like when it comes to REACh am I want the system to carry out Exposure Assessment for me? Want to generate eSDS? Capture plant to plant substance management? Like that creating a list of requirements would be a good starting point. 2) Once the requirement are understood – then start prioritizing the needs like which one the company needs to manage and which are nice to have / good to have features 3) Once you prioritize the requirements then assess the software in the market by reading their product brochures and also customer demo packages 4) Once their information is understood then start working on the infrastructural requirement in terms of Hardware / Software package their availability in the market etc. 5) Besides the above there many other questions which needs to be assessed from integration, custom enhancements, performance factors, learning curve, availability of best practices etc.

Thanks

Now that majority of companies are seeing for expanding their EHS portfolio by implementing additional software components – it needs some research and understanding which software fits to the company. Even companies are not without any software processes– they have been operating with some internal tools and other application components to meet their day to day regulatory requirement. Now that they want to move out of the legacy tools and migrate to enterprise levels – they have some solutions in mind –either develop own tool, use software as a service or use the established tool from the ERP vendors on premise. The development of custom tools may seem attractive initially but the quality depends on the ability of the resource guiding its development and has a long term liability of support and maintenance – should only be driven by a strategic requirements.

When it comes to external software components there are many of products available in the market today each one promising its own ROI. So before a product is purchased some of the questions which needs to be assessed include – 1) what I am seeing for the product to do? Like GHS reporting, GHS management in Supply Chain, Product portfolio management using the Environmental information. So on depending on the module of interest? Like when it comes to REACh am I want the system to carry out Exposure Assessment for me? Want to generate eSDS? Capture plant to plant substance management? Like that creating a list of requirements would be a good starting point. 2) Once the requirement are understood – then start prioritizing the needs like which one the company needs to manage and which are nice to have / good to have features 3) Once you prioritize the requirements then assess the software in the market by reading their product brochures and also customer demo packages 4) Once their information is understood then start working on the infrastructural requirement in terms of Hardware / Software package their availability in the market etc. 5) Besides the above there many other questions which needs to be assessed from integration, custom enhancements, performance factors, learning curve, availability of best practices etc.

Thanks

Subscribe to:

Posts (Atom)